Forward progress finally got a bit faster. I had a lot of trouble with the top of the bench, getting it smoother out. I used a hand plane to do 95% of the work, and that did work for the most part. I had a lot of trouble with tearout, the plane blade tearing away wood, digging far deeper than the blade would have cut. I had to stop with the plane. I tried using a back bevel on the blade to increase the angle for less tearout, which I think helped, however I was still having the issue. I switched to sanding, an extremely tedious workout! I didn’t know how else to get it flat. Remember, this is the entire top of the bench, far too large to go into the 13″ planer.

Working with the very large pieces is pretty new to me also, having to turn the legs 180 degrees to be able to cut them shorter, and having to open the door to the shop, so when I ripped the long stretchers to final shape, I had room for them to exit the table saw. Most of my shop tools are shoved to one side of the shop, to make room for the top, which is setting on the floor, on some carpet remnants. It’s very hard to work on the top when it is on the floor.

I am aiming for a high quality workbench, so I am taking my time with it. I’m also terrified I’ll make a wrong cut, so I am really trying to measure things a bunch of times, rethink the cuts through, and visualizing each piece to make sure I’m putting tenons on the right side of the piece. So far I’ve made no huge mistakes!

The short tenons need to be a precise length so that after being inserted into the legs, the entire width is exactly the width of the top. I am leaving quite an overhang at both ends of the workbench top, so the long stretchers aren’t terribly long. The overhang on both ends of the workbench, past the ends of the legs is about 15″. I am using my digital calipers where I can, to make sure everything is cut super accurate.

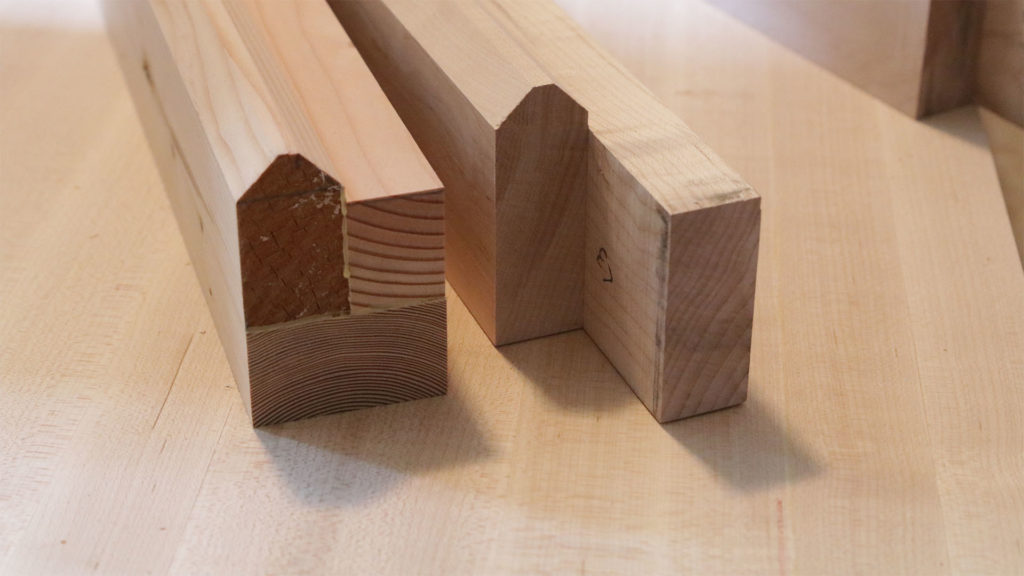

Because of an issue jointing and planing the leg pieces, my legs ended up 4.75″ by 5″ instead of 5 x 5″ as described in Christopher Schwarz’s book. I don’t think this is anything critical or course, however, I made the long stretcher tenons 2 3/8″ instead of 2.5″ because of this change.

I did make my long stretchers out of one piece of thicker maple. Because of this, I did cut the profile of the long stretcher on the table saw, starting by making and cutting on a test piece. Once I had a cut lined up on the test piece, which was the exact same width and height as the long stretchers, then I made the same cut in both of the long stretchers. I was able to cut the profile needed in the long stretcher with 4 cuts on the saw.

It won’t be long before I have more to report on here, the mortise have all been cut, and I just have a couple more things to do before I’m ready to assemble the base.

Equipment used in this build:

DEWALT DW7670 8-Inch 24-Tooth Stacked Dado Set

SawStop BTS-R-40ATB 40-Tooth Titanium Series Premium Woodworking Blade, 10-Inch with 5/8-Inch Arbor

Christopher Schwarz’s book Workbenches Revised Edition: From Design & Theory to Construction & Use

Digital Calipers http://amzn.to/2DnVhAw