After seeing a blue jay tear up the nest of some house finches, I decided to build a few bird houses, so maybe the house finches could have better luck in the future. I had some old lumber I got to use in the woodstove, and remembered some fence boards in the pile, so I went and got those. It looked like a future bird house to me!

I did a bit of research on bird houses. I found the oak titmouse needs about a 1.25″ hole, and a house finch needs about a 1.5″ entry hole. The house should be about 5 to 6″, and maybe 8 to 9″ tall. Do a little research for the types of birds you have. I also let the fence boards dictate the dimensions somewhat. I put a 10 degree tilt on it for the roof. The articles said not to put a perch or dowel under the entry hole, as this just gives the predators something to hold onto when trying to get in. The nesting birds can easily get in without a perch. Also they said to put some small holes up near the top for ventilation, and some in the bottom too. I tilted all these holes upwards, so water would tend to want to run out.

I used Titebond III waterproof glue, and 1.25″ screws that won’t rust to make the bird house. I’ve never used the Titebond III waterproof glue for an outside project before, so for me, this will be a bit of an experiment to see how that holds up over the years.

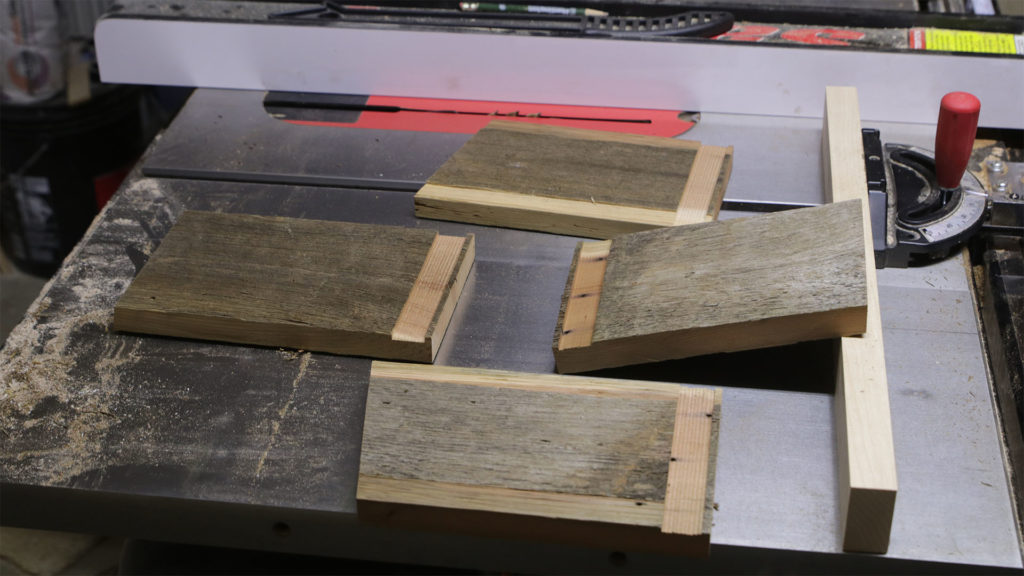

First of all, I carefully checked for nails. I don’t need a nail ruining my day in my SawStop saw. Activating the brake accidentally would be a costly mistake. Then I cleaned up the edges so when I made it, they would glue together well. That was my first mistake; I should have only cleaned the edges of the front and back pieces. I ended up putting rabbets in the sides, and could have left those edges as they were.

I didn’t really plan exact sizes for anything, and just cut pieces to whatever length, keeping in mind the 5-6″ dimensions for width and length, and 8 to 9″ tall. The top of the front and back pieces are beveled at 10 degrees, for the roof which is at a 10 degree angle. I started by cutting the sides with the top at a 10 degree angle, then used that piece to determine the heights for the front and back pieces.

When cutting the pieces out, I tried to make it so any nail holes from the old fence were in places where it wouldn’t matter, very near the bottom , or right up under the roof piece. Notice above the nail holes are across the dado for the bottom piece. The birds won’t get wet from those.

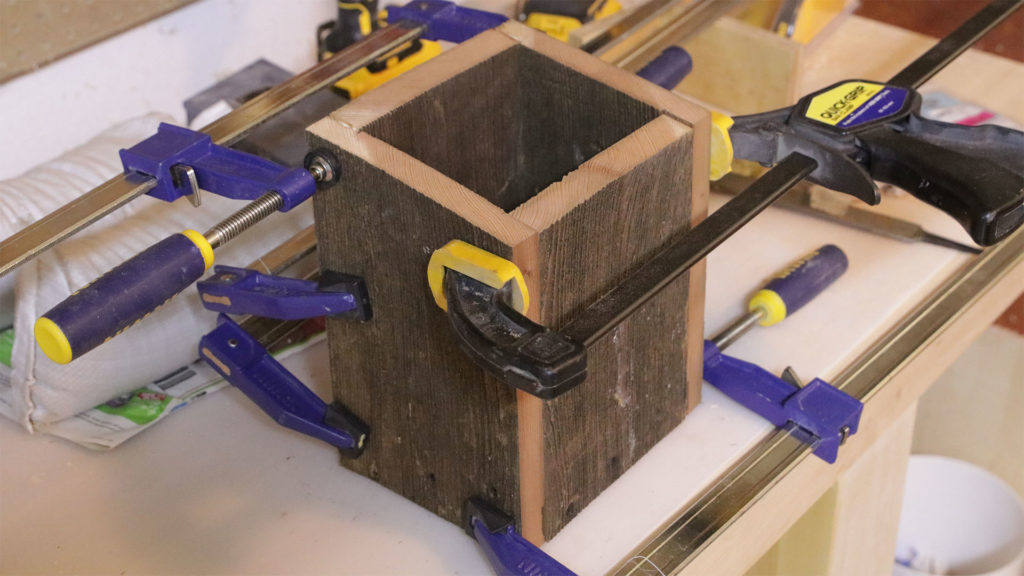

In the image above, the front piece is just sitting there, not glued, to help keep it square. The front piece is removable so the old nests can be cleaned out. I just screwed the front piece on by the sides to hold it in place. I’ll drill the entry hole in later. After this dried, I drilled countersink holes in the sides, and put screws in.

I mounted two narrow boards on the back that I attached screws to the top for putting a wire around and hanging it from a branch. Each of those boards has a small dado in it, so it will fit around the roof overhang (which I kept minimal in the back of the house).

I ended up just gluing the tops on, after I chiseled a shallow dado for the sides to fit in. This dado will let any water running along the bottom edge of the top to not be able to run into the inside of the birdhouse. Should I have also screwed the tops on? I don’t know. Another experiment to find out how that works over the years. I hope the birds are happy! In the past, all birdhouses I’ve ever had are used pretty much every single year, so I expect these to be used soon.

Products used in this build:

1.25″ screws that won’t rust: https://amzn.to/2KTOov0

Titebond III waterproof glue: https://amzn.to/2rErWy5

Countersink drill bits: https://amzn.to/2jRJClB

Forstner bit set: https://amzn.to/2rJWQ7F

Big Tools I use:

Table Saw, SawStop PCS: http://amzn.to/2H3ySLb

SawStop Industrial Mobile base: http://amzn.to/2spo6f6

Overarm dust collector: http://amzn.to/2CdfRlR

SawStop 80 tooth blade: http://amzn.to/2Cenngl

SawStop 40 tooth blade: http://amzn.to/2CdLRXh

SawStop Dado safety cartridge: http://amzn.to/2H8e7ye

DeWalt Dado: http://amzn.to/2CeqLrs

SawStop Cast Iron Extension: http://amzn.to/2Cdtj9s

Bench Dog Router Extension: http://amzn.to/2Bpcbkr

Router: http://amzn.to/2H5YK9v

Router Lift: http://amzn.to/2Ejz3En

Band Saw: http://amzn.to/2Eh9pQG

Smaller Tools I use:

DeWalt Drill/Driver set (very nice!): http://amzn.to/2BpDMC7

Clamps: http://amzn.to/2H6tG9t

Bessey REVO Clamps: http://amzn.to/2CeGEOJ

FastCap Glue Bottle: http://amzn.to/2Cf25z5

Chisel set: http://amzn.to/2EVBUAD

Brad point drill bits: http://www.leevalley.com/us/wood/page.aspx?c=&p=42247&cat=1,180

Forstner Bit Extension: http://amzn.to/2CdxB0r

Bubble Level: http://amzn.to/2Elvr50

Sharpening Stones:

DMT 8″ Course (D8C): http://amzn.to/2hZ8AOO

DMT 8″ Fine (D8F): http://amzn.to/2hY4tCT

DMT 8″ X Fine (D8E): http://amzn.to/2Agtofq

DMT 8″ XX Fine (D8EE): http://amzn.to/2BwMziU

Safety Equipment:

Dewalt safety glasses: http://amzn.to/2Dp5ZpW

Dewalt safety glasses Rx-BiFocal (choose your power): http://amzn.to/2FFV2lw

Dust masks N95: http://amzn.to/2HynRRH

Hearing protection: http://amzn.to/2FPrV3v

Camera Equipment:

80D: http://amzn.to/2EUq5KV

Lens: http://amzn.to/2CdJKCs

GoPro: http://amzn.to/2BnQa5h

Sandpaper:

3M 100: http://amzn.to/2EiI94g

3M 220: http://amzn.to/2H8us5K